Sartorius

Bioburden and Biofilm Management in Pharmaceutical Operations

Perspective of Aseptic Sampling

Microbial control is a major objective for all sterile drug manufacturers, with bioburden reduction representing a significant share of risk mitigation efforts.

The Parenteral Drug Association recently released PDA Technical Report No. 69: Bioburden and Biofilm Management in Pharmaceutical Operations, which provides background on the causes and control strategies of bioburden in pharmaceutical production processes, as well as the risks of biofilm, the challenges of removing it, and strategies to help reduce the incidence of biofilm formation.

The document emphasizes the importance of sampling throughout the process, from upstream manufacturing through downstream purification, culminating in bulk and final filling operations.

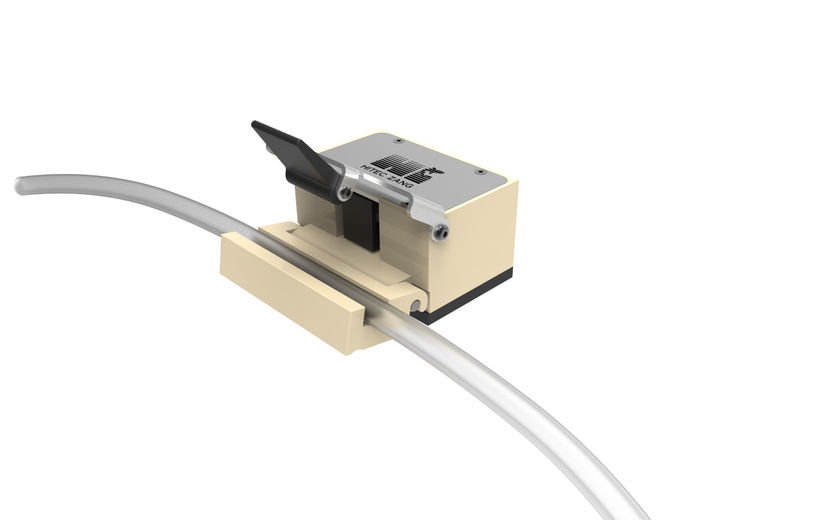

PDA Technical Report No. 69 strongly suggests the use of aseptic/sterile sampling devices. Alternative sampling methods can lead to false positive results, and can contribute to process fouling by bioburden and biofilm formation.

This white paper delves deeper into aseptic sampling devices to explain how they offer superior performance in the effort to control contamination.

Advertisement

White Paper classification

White papers on related topics

Products on related topics

Manufacturers of similar products

See the theme worlds for related content

Topic world biopharmaceutical manufacturing

Biopharmaceutical production plays a crucial role in the development and manufacture of biologics, which are essential for the treatment of various serious diseases. Various key technologies and processes of the modern biopharmaceutical industry are used, such as cell cultures, fermentation processes and the purification of biological substances, which are necessary for the production of vaccines, monoclonal antibodies and other biological drugs.

Topic world biopharmaceutical manufacturing

Biopharmaceutical production plays a crucial role in the development and manufacture of biologics, which are essential for the treatment of various serious diseases. Various key technologies and processes of the modern biopharmaceutical industry are used, such as cell cultures, fermentation processes and the purification of biological substances, which are necessary for the production of vaccines, monoclonal antibodies and other biological drugs.